-

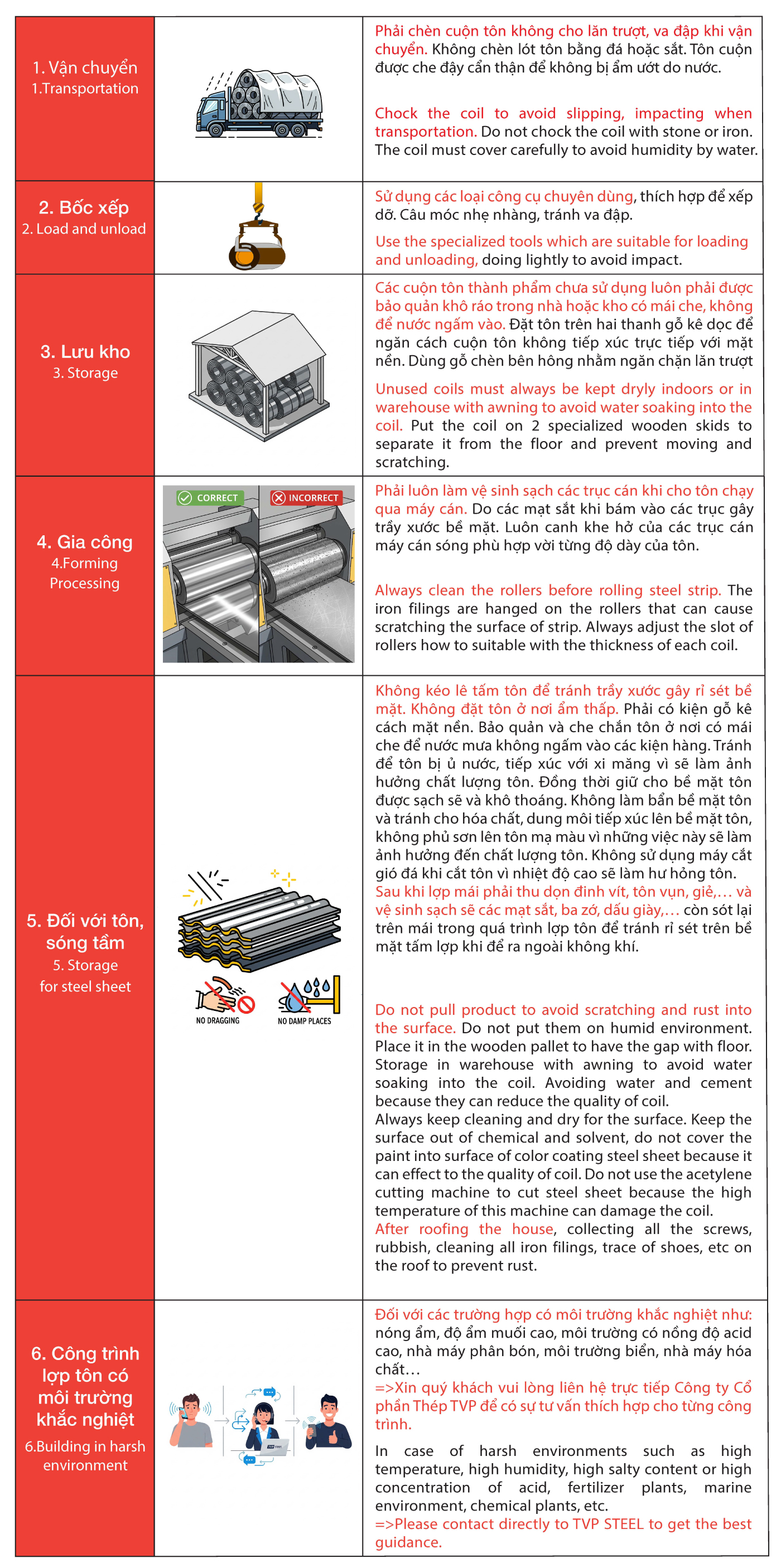

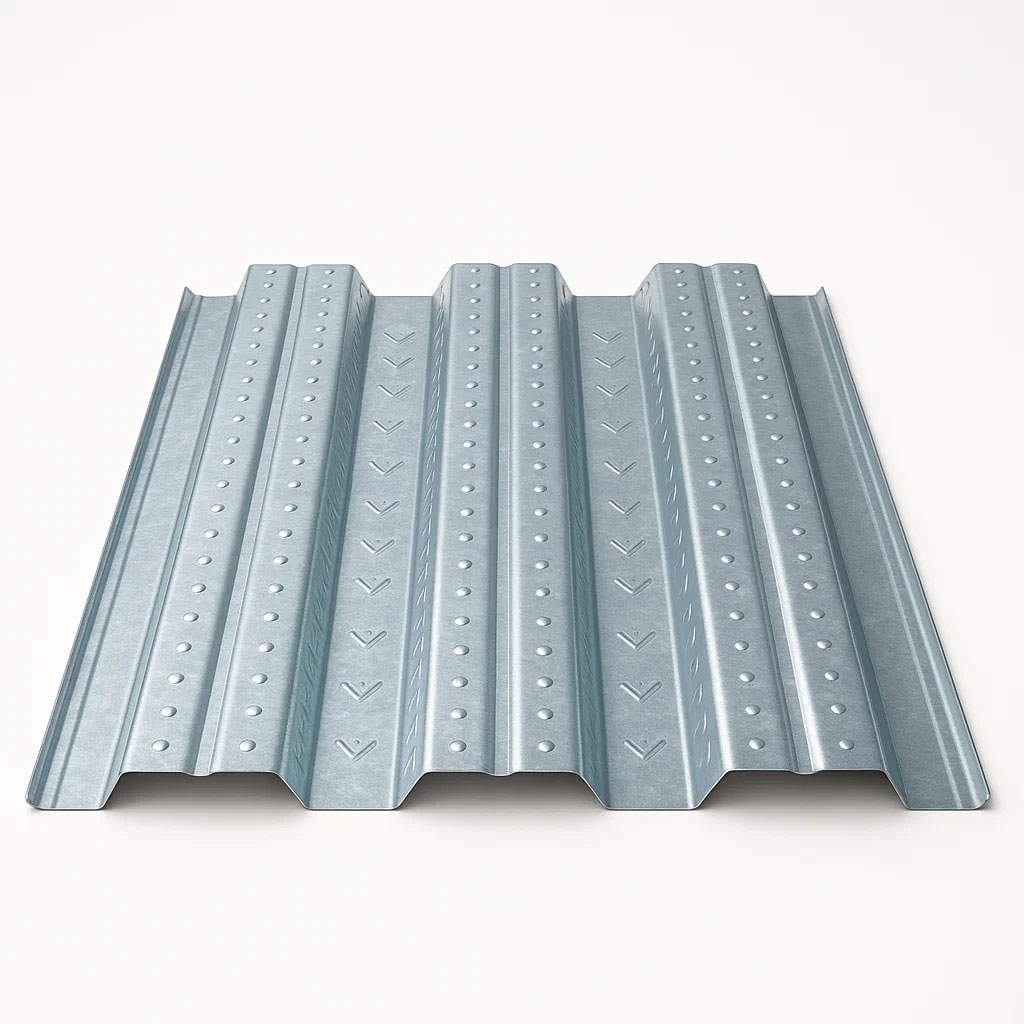

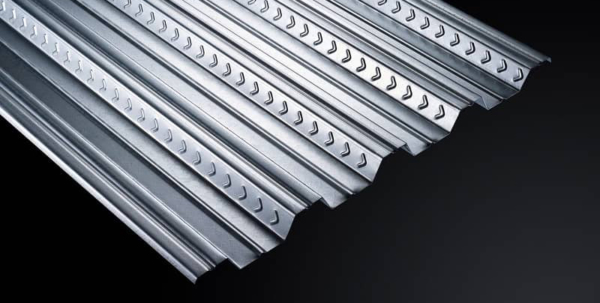

Corrugation type2U, 3U, 4U, perforated anti-slip ribs, and reinforced stiffening ribs

-

ColorOriginal metal finish / Customizable upon request

-

Corrugation heightH = 50 mm, 71 mm, 75 mm

-

Tensile strength of floor deck steelG300 - G550

-

Thickness0,75 - 2,5 mm

-

LengthCut to project-specific requirements

-

Base steelGalvanized steel / Aluzinc alloy (Al-Zn) / Aluminum-Zinc-Magnesium alloy (Al-Zn-Mg)

Product description

What is Steel Deck?

TVP Steel Deck is a high-quality profiled sheet used in reinforced concrete floor construction. With its ribbed structure and excellent load-bearing capacity, it is an effective alternative to traditional formwork—helping reduce costs and speed up construction.

5 KEY ADVANTAGES

OF TVP STEEL DECK

– Cost saving on materials and labor compared to traditional formwork.

– Faster installation time, easy to transport and assemble.

– Enhanced load capacity, creates a solid bond between steel and concrete.

– Excellent corrosion resistance, durable in harsh environments.

– Versatile application for residential, high-rise, factory, and commercial projects.

Structure of Steel Deck

Steel deck consists of three main components:

- – Profiled steel sheet (deck): Made from galvanized or alloy-coated steel, acts as permanent formwork and a main load-bearing layer during construction.

- – Cast-in-place concrete: Directly bonded to the deck surface via mechanical interlock from wave and punching design.

- – Reinforcement steel (if needed): Additional rebar placed on or within the concrete layer for structural strength.

- Install steel beams or structural frames.

- Place the steel deck panels on the frame, fix using screws or spot welding.

- Install reinforcement mesh if required by design.

- Pour fresh concrete directly, use a vibrator to ensure compaction and bonding.

- Cure the concrete and finish the surface.

⏱ Construction time is 30–40% faster compared to traditional formwork, while reducing scaffolding, labor, and project management costs.

Production Standards

& Quality Inspection

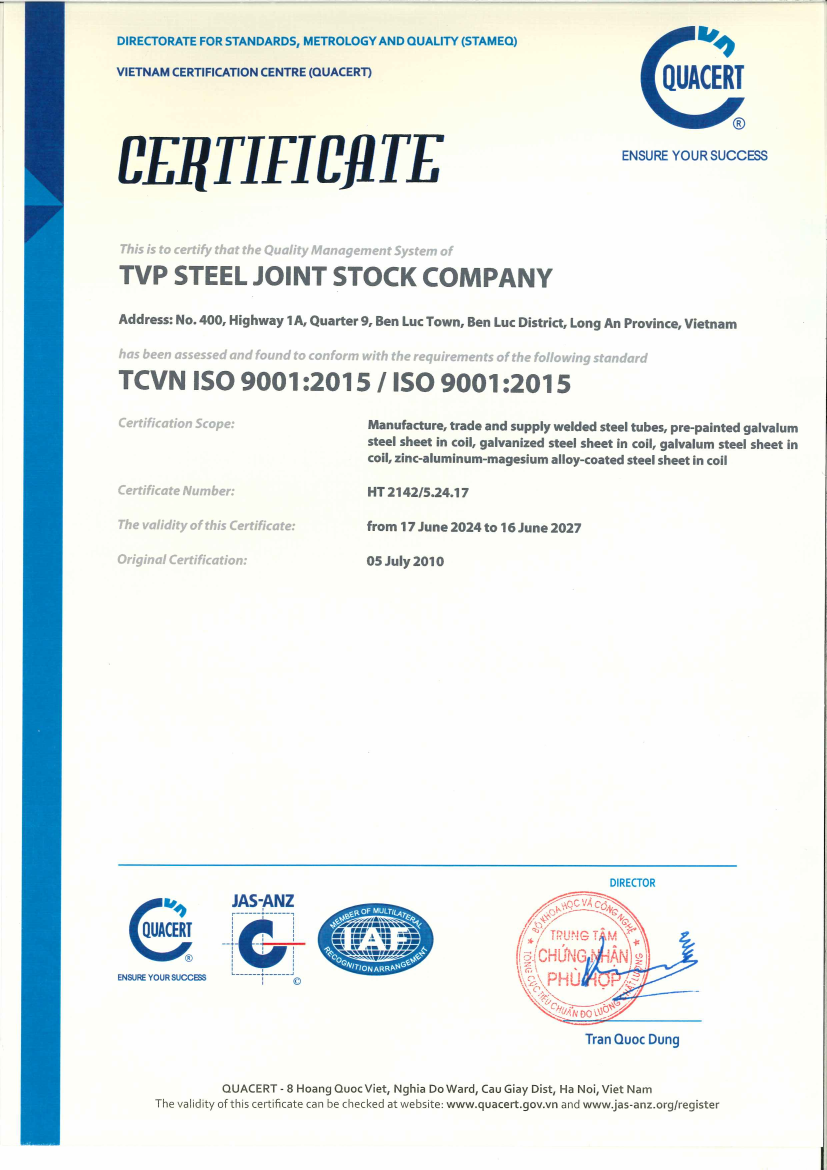

TVP Steel Deck products are manufactured according to:

- ASTM A653 (USA): for galvanized steel substrate.

- JIS G3302 (Japan): ensuring ductility and corrosion resistance.

- ISO 9001:2015: applied for quality management systems at the factory.

Each batch is tested for coating thickness, steel hardness, tensile strength, dimensional accuracy, and slip resistance with concrete bonding.

Comparison: Steel Deck vs. Traditional Formwork

| Criteria | TVP Steel Deck | Traditional Formwork |

|---|---|---|

| Construction speed | Fast (1–2 days) | Slow (3–5+ days) |

| Material reuse | No removal needed, stays in place | Must be removed, prone to damage |

| Load capacity | Excellent (3-layer bonding) | Depends on concrete alone |

| Safety during installation | High | Moderate |

| Overall cost | 10–20% savings | Higher due to labor and scaffolding |

Common Types of Steel Deck by TVP

| Rib Type | Key Technical Features | Primary Applications |

|---|---|---|

| 2U Rib | Single rib profile, easy installation, ideal for residential use | Low-rise houses, small offices |

| 3U Rib | Deep stiffening ribs, high load capacity | Factories, high-rise buildings |

| 4U Rib | Strong concrete bonding, for long-span beams | Shopping malls, warehouses |

| Perforated Rib | Optimized anti-slip, enhances concrete adhesion | Sloped floors, vibration-resistant floors |

Latest Steel Deck Weight Table 2025

| Post-Coating Thickness (T mm) |

Raw Coil Width (L mm) |

Effective Width (L mm) |

Rib Height (H mm) |

Post-Coating Weight (P kg/m) |

Coating Mass (Z g/m²) |

Tensile Strength (TS N/mm²) |

Base Steel Hardness (H hrb) |

Moment of Inertia (cm⁴/m) |

Section Modulus (cm³/m) |

|---|---|---|---|---|---|---|---|---|---|

| 0.58 | 1200 | 1000 | 50 | 5.54 | 80–120 | 355–368 | 58 | 51.2 | 16.43 |

| 0.75 | 1200 | 1000 | 50 | 7.15 | 80–120 | 355–368 | 58 | 61.7 | 20.11 |

| 0.95 | 1200 | 1000 | 50 | 9.05 | 80–120 | 355–368 | 58 | 68.91 | 25.19 |

| 1.15 | 1200 | 1000 | 50 | 11.1 | 80–120 | 355–368 | 58 | 76.76 | 28.47 |

| 1.5 | 1200 | 1000 | 50 | 14.2 | 80–120 | 355–368 | 58 | 93.39 | 34.02 |

Contact us now for consultation and a quick quote!

TVP STEEL JOINT STOCK COMPANY

Address: [No. 400, National Road 1A, Quarter 9, Ben Luc Town, Ben Luc District, Long An Province, Vietnam]

Hotline: 0917 242 655 (Zalo / Call 24/7)

Email: kinhdoanh@tvpsteel.vn

Website: www.tvpsteel.vn

Quick order – On-time delivery – On-site technical support!

PRODUCTION LINE

Máy Cán Sàn Deck

STORAGE INSTRUCTIONS